6 Step Manufacturing Process Built on Experience, Refined for Results

Our proven methodology ensures quality, efficiency, and success at every stage of your manufacturing project.

Step 1: Discovery & Consultation

Where Ideas Become Action Plans

"Our process begins with strategic alignment—diving deep into your goals, technical needs, and timeline to build a precise and scalable solution."

⏱ Duration: 1 to 2 Days

- Requirements AnalysisUse cases, material needs, technical specs, and functional requirements to define the scope are analyzed.

- Feasibility AssessmentProject viability against budget, available resources, and constraints is evaluated.

- Budget & Timeline EstimateBudgets and schedules are built on real data and clear expectations are communicated.

⏱ Avg. First Response Time: Less Than 2 hours

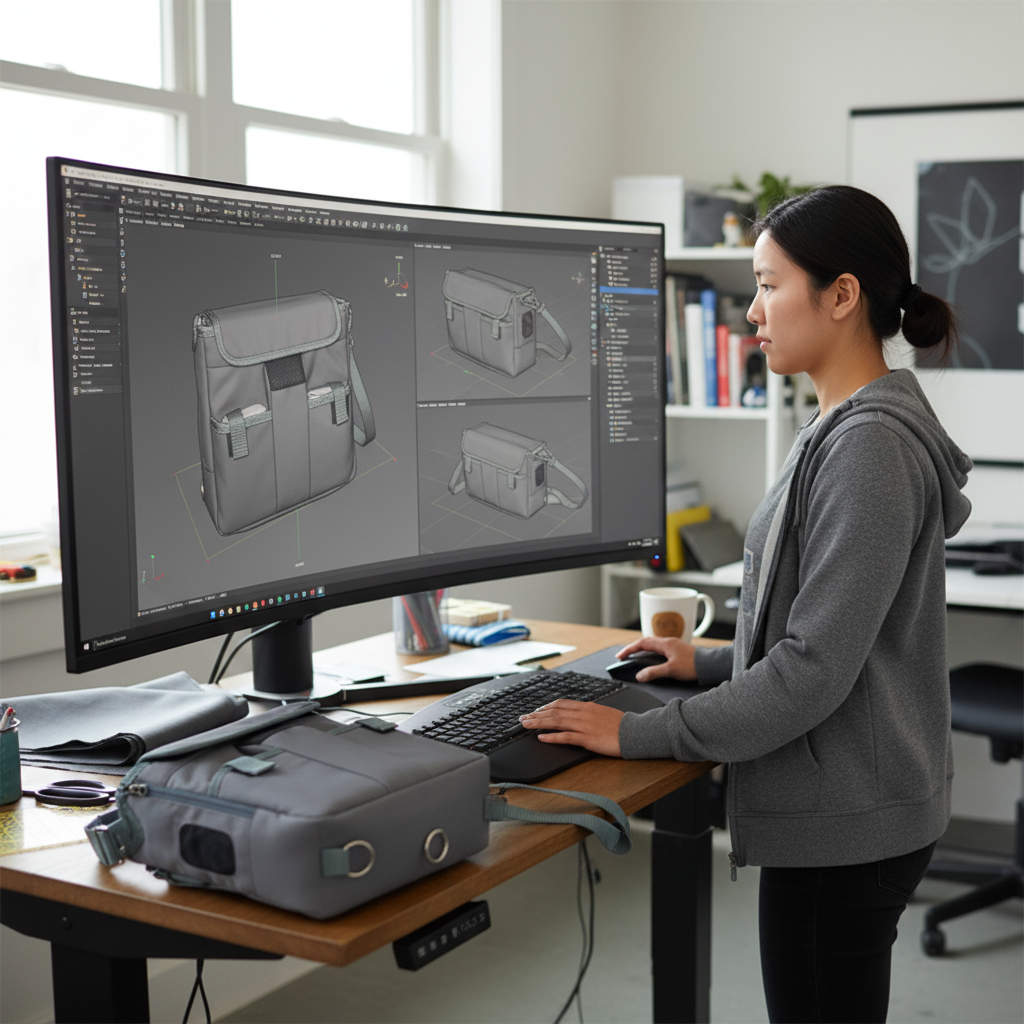

Step 2: Design & Engineering

Converting Concepts into Production-ready Designs

⏱ Duration: 1 to 2 Weeks

- 3D Modeling and CAD DesignDetailed CAD files, material specs, and refined designs are created to turn concepts into manufacturing-ready products built for scale.

- Material Selection and SourcingMaterials are chosen and sourced that meet your product’s requirements, budget, and timeline.

- Manufacturing OptimizationDesigns are refined so they can be produced efficiently, cost-effectively, and at scale without sacrificing quality.

Step 3: Rapid Prototyping

Testing Early, Perfecting Faster

⏱ Duration: 3 to 7 Days

- Functional TestingPrototypes are tested in real-world conditions to check material strength, durability, and performance.

- Design IterationFeedback and test results are used to refine the prototype and improve the design.

- Client Approval ProcessFinished samples are provided for hands-on review, evaluation, and sign-off before production.

⚡ Prototype Turnaround: 48 hours from design to physical sample

Step 4: Production Planning

When Strategy Meets Execution

⏱ Duration: 2 to 3 Days

- Resource AllocationEquipment, materials, and personnel are scheduled for efficient production.

- Quality Control Framework Checkpoints and standards are defined to ensure consistent quality during manufacturing.

- Timeline and Milestones Clear deliverables and communication checkpoints are established for predictable execution.

📅 On-Time Delivery Rate: 96% consistent project execution

Step 5: Manufacturing & Production

Precision Meets Scale

⏱ Duration: 1 to 4 Weeks

- Quality Control at Every Stage Products undergo multi-point inspections to ensure consistency from start to finish.

- Real Time Monitoring Production progress, quality metrics, and delivery timelines are tracked live.

- Scalable Production Capacity is available for both small runs and high-volume production.

🏆 Defect Rate: < 0.1% industry-leading quality standards

Step 6: Quality Assurance & Delivery

Final Inspection, Packaging, and Logistics Coordination

"Comprehensive final inspection, packaging, and logistics coordination ensure your products arrive exactly as specified, on time and ready for use."

⏱ Duration: 1 to 3 Days

- Final Inspection Finished products go through comprehensive testing and validation before shipment.

- Custom Packaging Protective packaging is designed to safeguard products based on their requirements.

- Logistics Coordination Shipping partners and tracking are managed to ensure reliable delivery.

⭐ Customer Satisfaction: 99.2% measured by repeat business